The use of filters in the Cola production process is crucial. Filters not only guarantee the quality and safety of the product, but also improve production efficiency and environmental friendliness.

1. Microbiological quality control

- Drinking water filtration: The Coke production process is strictly monitored from the water treatment stage. High-quality filters such as those produced by HUANZHENG are used to ensure that drinking water meets purity standards and to prevent the growth of microorganisms.

- Microbiological testing: Microbiological limit checks are carried out using membrane filtration, where pathogenic bacteria, yeasts and molds trapped on the filter membrane are cultured for total bacterial counts, thus effectively controlling product quality and safety.

2. Ingredient and additive filtration

-Concentrate and flavor filtration: During the process of diluting appropriate concentrates and adding relevant flavors, filters are used to remove impurities that may have been mixed in and to ensure the consistency and purity of the beverage's taste.

- Syrup and other additives filtration: Simple syrups (sweetened water) and final syrups (specialized concentrates plus simple syrups) also need to be filtered during production to ensure that they are free from particulate matter and microbial contamination.

3. Carbonation and mixing process

- Carbonation Filter: During the production of carbonated beverages, carbon dioxide needs to be filtered through specially designed filters to ensure its purity and to avoid the introduction of foreign substances or microorganisms.

- Mixing process filtration: During the mixing process of carbonated beverages, filters are used to remove impurities from air or other gases that may be mixed in to ensure the quality of the beverage.

4. Packaging and storage

- Aseptic air filtration: Aseptic air filters are used to ensure that the air in the blown bottle or tank breather is sterile and to prevent secondary contamination.

- Tank Ventilation Filtration: Tanks need to be ventilated during storage, and filters are used to remove airborne particles and microorganisms to keep the inside of the tank clean.

5. Steam and dry filtration

- Steam Filtration: Steam is used to sterilize cartridges and equipment, and filters are used to ensure the purity of the steam during the process to prevent the introduction of impurities.

- Dryer Filtration: Adsorption dryers are used to treat moisture and impurities in compressed air to ensure that the compressed air used in the production process is clean and free from contamination.

6. Environmental and emission control

- Wastewater treatment: Wastewater generated in the production process needs to be treated through the filtration system in order to meet the discharge standard and reduce the pollution to the environment.

- Exhaust gas filtration: The exhaust gas generated in the production process also needs to be treated through the filtration system to remove harmful substances and protect the environment.

7. Energy efficiency and cost control

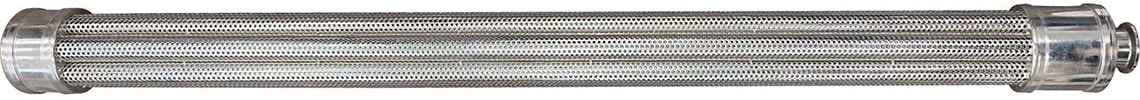

- High efficiency filtration systems: The use of high-flow filtration systems such as angle filters and basket strainers improves filtration efficiency and reduces energy consumption and operating costs.

- Easy Maintenance: Modern filter designs emphasize easy maintenance and replacement, reducing downtime and maintenance costs.

8. Regulatory compliance and certification

- International standards: Filters are used in accordance with ISO implementation guidelines as well as local regulatory requirements to ensure that production processes are legally compliant.

- Total Quality Management System (TQMS): Cola has implemented a Total Quality Management System (TQMS) to ensure overall production quality through internal and external audits to assess quality control standards and effectiveness, with filters as an important part of this system.

In addition, the following points are worth noting when choosing and using filters:

- Choosing the right type of filter: according to different production processes and needs, choose the right type of filter, such as pre-filter, security filter, decontamination filter, etc. HUANZHENG is committed to producing and providing high-quality filter housings and filter elements, with nearly 20 years of production and sales experience.

- Regular replacement and maintenance: Filters need to be replaced and maintained regularly to maintain their filtration effect and prolong their service life.

- Train operators: Provide professional training to operators to ensure that they understand the correct use of filters and maintenance techniques.

Overall, filters play multiple roles in the production process of cola, from the quality control of raw materials to the safety guarantee of finished products, throughout the entire production process. With an efficient filtration system, not only does the product quality and production efficiency improve, but it also meets the requirements of environmental protection and sustainable development.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved