How Many Types Of Stainless Steel Sintered Mesh?

Stainelss steel Sintered wire mesh is a good filtration material, it has wide range of filtration accuracy; stable filtration accuracy; good strength; easy to clean; high temperature resistance; corrosion resistance and easy to process etc. characteristic. Widly used on process of food and beverage, water treatment, power plant dust removal, pharmecutical, pertroleum, film and other industries.

How many Types of sintered mesh? and how many types of sintered mesh? how about its structure? as a professional manufacturer, ZHEHAN can answer you:

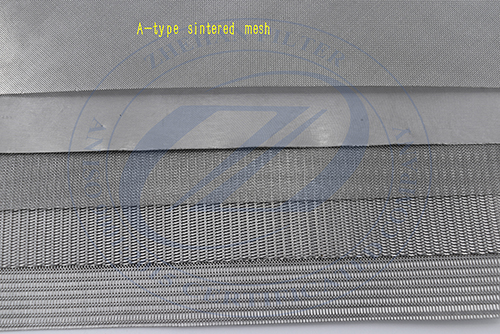

1. A-type sintered mesh

This is the most widely used standard structure sintered mesh. It is a porous sintered material made by stacking five layers of stainless steel wire mesh according to different structures, and then sintering, pressing, rolling and other processes. Mainly used in food and beverage, water treatment, power plant dust removal, pharmaceutical, film and other industries. It can be processed into cylinder, disc and disc filters.

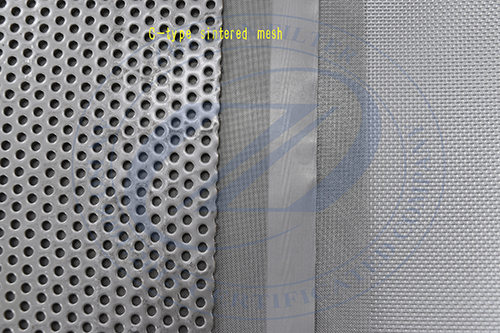

2. B-type Sintered mesh

B-type of a sintered mesh made of a multi-layer plain weave square mesh. Due to the high opening rate of the square mesh, the sintered mesh has the characteristics of high air permeability, low resistance, and large circulation. Mainly used in the filtration of various gases and liquids. Since each layer of wire mesh has greater selectivity, its structure can be customized according to user requirements.

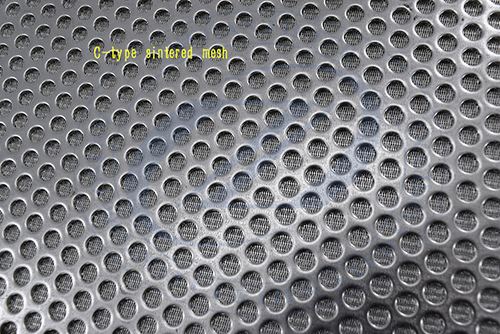

3. C-type sintered mesh

The product is a kind of sintered mesh which sintered with a punching plate and multi-layer stainless steel wire mesh. The compressive strength and mechanical strength of sintered mesh is higher because of the support of the punching plate. Mainly used in food and beverage, water treatment, power plant dust removal, pharmaceutical, film and other industries. It can be processed into cylinder, disc, and disc filters. The thickness of the punching plate and the structure of the screen can be customized according to user requirements.

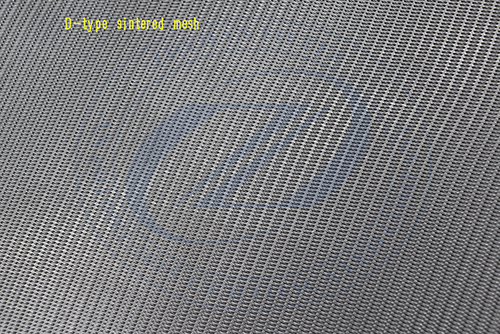

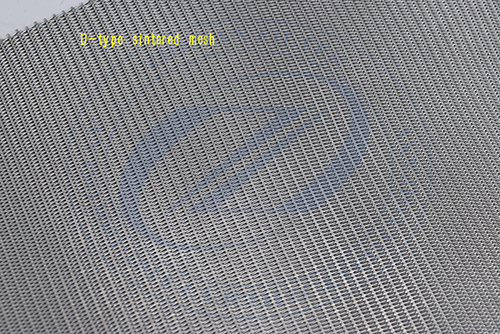

4. D-type sintered mesh

This is a sintered mesh made by stacking two or three layers of plain weave dutch meshes with the same precision together through sintering, pressing, rolling and other processes. It has the characteristics of uniform holes and stable air permeability. Mainly used in fluidized bed, powder conveying, silencer, drying, cooling and other industries fields.

Characteristic

-Wide range of filtration accuracy

Reliable filtration performance from 1 micron to 200 micron.

-Stable filtration accuracy

Because there are two layers of wire mesh for protection, and the sintering process of diffusion and solidification, make sure the mesh of the filter layer is not easy to deform.

-Good strength

Due to the support of the fourth and fifth layers, it has high pressure resistance and mechanical strength.

-High temperature resistance

Can withstand high temperature of 600℃.

-Corrosion resistance

Due to the use of SUS316L material, it has high corrosion resistance.

-Easy to process

It is suitable for cutting, bending, stamping, stretching, welding etc.

Material

Standard material SUS304, SUS316 (AISI 316)(AISI 304), SUS316L(AISI 316L)

Size

The standard size is 500×1000mm, 600×1200mm. The size within the above range can be customized according to user requirements.

ZHEHAN FILTER is an ISO9001:2015 certificated company, manufacturer of stainless steel filter elments, sintered wire mesh is one of main prodcuts, we have bulk stock in hand

welcome to contact us or leave message if you want to get more informations.

Copyright © Hebei Huanzheng Filter Equipment Co., Ltd. All Rights Reserved